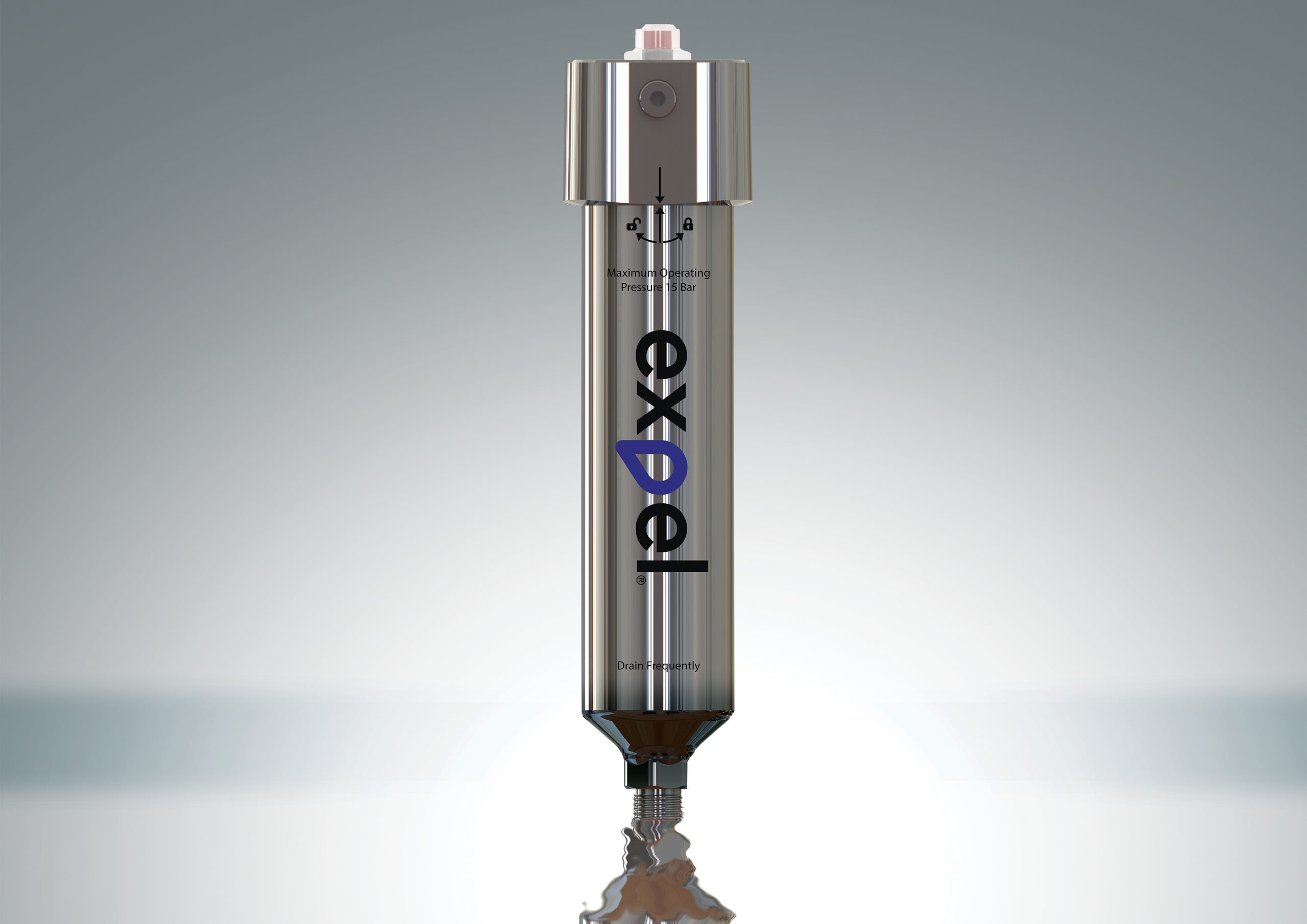

Expel continually removes 99.999% of ALL liquids and solid particulates down to 1 micron

The Expel requires no replacement filter elements and has been manufactured so it is built to last to keep ongoing costs and wastage to a minimum

BENEFITS

Reduces Downtime

Reduces Costs

Reduces Maintenance

Protect Equipment

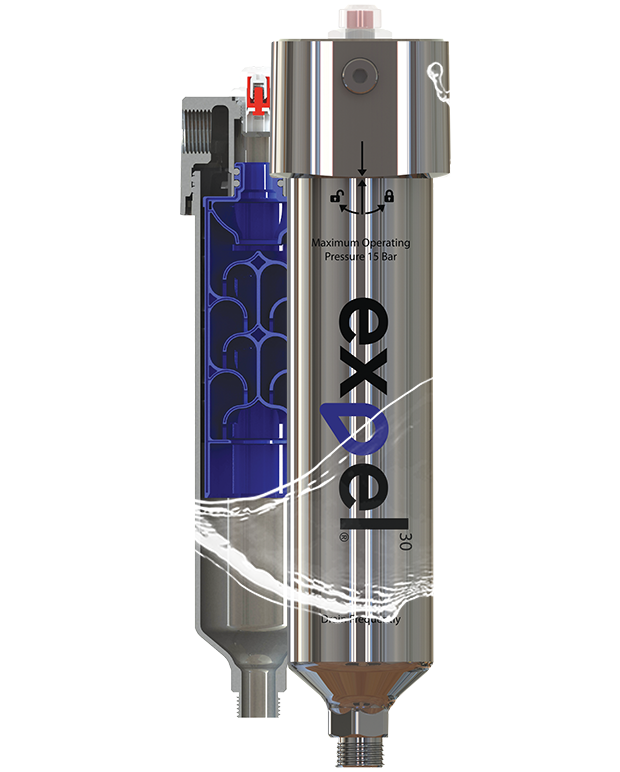

Traditional filter vs Expel

Traditional

expel

Efficiency

60-80%

99.9999%

Reduced efficiency

over time?

yes

no

Pressure bar drop

0.5 bar (average) which increases with use

0.1 bar (consistent)

Frequency of part replacement

3-12 months

never

Maintenance required?

yes

no

Warranty

NO

10 years

VIDEOS

We have gathered feedback from our existing customers across a variety of industries, so that you can have honest opinions about the effectiveness and quality of Expel.

EXPEL range

We have several Expel models with different technical specifications to suit your specific site set up, why not take a look at our Expel specifications page to find out which Expel will work best for your application?

AUTO DRAINS

We recommend that one of our state-of-the-art Auto Drains be attached to every Expel unit purchased. All of our drains are automatic, corrosion-resistant, and easily maintained.